News

Jan

15

2026

Domtar Improves CDP Scores in First Integrated Disclosure

BY: Lauren Fisher Domtar’s CDP scores reflect our first disclosure as an integrated company for climate change, water security and forests. In 2025,...

Jan

06

2026

A Modern Guide to Curbside Recycling

BY: Colleen Marble By now, everyone’s heard the mantra “reduce, reuse, recycle.” But when it comes to curbside recycling, there’s still a lot of...

Dec

17

2025

Domtar Kingsport, USW Local 12943 Join Forces for Community Food Drive

Representatives from Domtar Kingsport, United Steelworkers Local 12943, Healthy Kingsport and Kingsport City Schools’ Family Resource Center pose with donated food and...

Dec

03

2025

Employee Grant Boosts Kingsport Literacy Initiative United WE READ

Kelsie Dulaney, center, impact and education manager with the United Way of Greater Kingsport, receives a $2,000 check from Domtar Kingsport’s Ellie Mitchell, left, and...

Dec

01

2025

Domtar Kingsport Hosts Chamber Leadership Class

Domtar employees Austin Phillips and Tori Johnson joined the Leadership Kingsport Class of 2026 during a mill visit, highlighting the lasting impact of the program on...

Oct

14

2025

Domtar’s Kingsport Mill Receives National Recognition for Sustainable Leadership

(Left to Right) Jan Martin, director of communications and public affairs, Domtar; Peter Adrian, chairman, NRC Board of Directors; Teresa Bradley, president, NRC Board...

Sep

16

2025

Domtar Supports Holston Valley Medical Center’s 90 Years of Service Campaign with $2,500 Contribution

Domtar’s Kingsport Mill has donated $2,500 to Ballad Health’s Holston Valley Medical Center in support of the hospital’s “90 Years of Service” campaign. The...

Jul

16

2025

Barrels of Fun: Domtar Celebrates Fun Fest with Annual Paint-In

Once again, Domtar Kingsport Mill team members participated in the annual Keep Kingsport Beautiful Trash Barrel Paint-In at the Allandale Mansion. For the 10th...

Apr

22

2025

A Living Tribute to Environmental Leadership

By Ellie Mitchell, HR Generalist | Kingsport Mill Bonnie Depew, the Kingsport Mill’s environmental manager, was honored with a Tennessee Tulip Poplar tree planted on...

Apr

03

2025

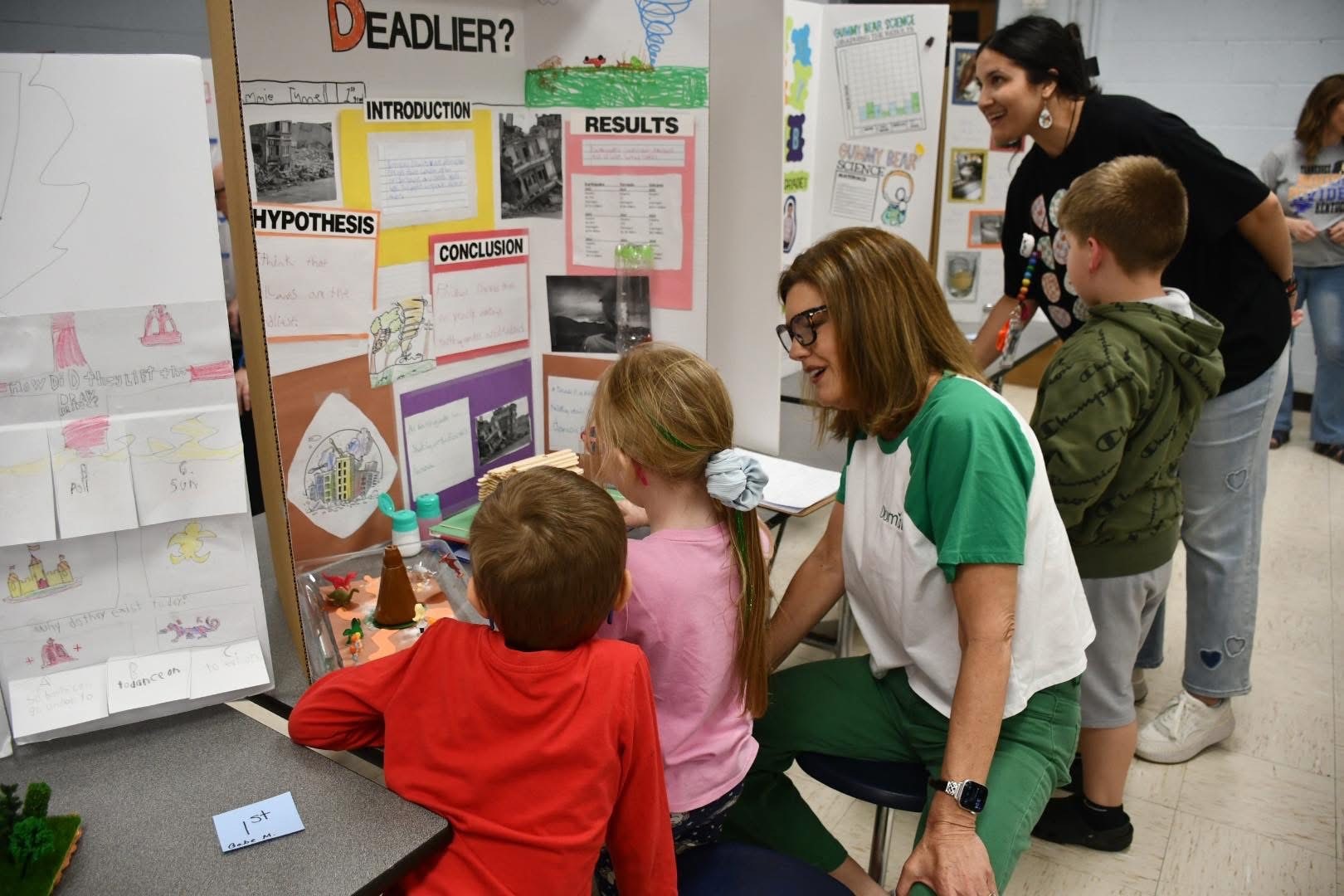

Mount Carmel Science Fair Showcases Students’ ‘Enthusiasm for Discovery’

By Julia Ives, Purchasing Manager | Kingsport Mill Julia Ives, purchasing manager at Domtar’s Kingsport Mill, discusses an entry with Mount Carmel Elementary...

Mar

15

2025

Ted Wiggins Reflects on More Than 40 Years at Mill

By Ellie Mitchell, HR Generalist | Kingsport Mill Ted Wiggins retired from Domtar’s Kingsport Mill after 43 years of service. He said the best advice he could...

Mar

10

2025

Celebrating the Joy of Reading!

By Ellie Mitchell, HR Generalist | Kingsport Mill Reading to Roosevelt Elementary students during Read Across America Week were Domtar employees, from left, Dan...

Mar

03

2025

Domtar’s Bill Edwards Honored with ASPI Excellence in Leadership Award

FORT MILL, SC, February 27, 2025 – Bill Edwards, Domtar’s senior vice president of Paper and Packaging Operations, received the prestigious Excellence in Leadership...

Feb

14

2025

Domtar Approves Project to Install State-of-the-Art Wastewater Treatment System at Kingsport Packaging Mill

KINGSPORT, Tenn. – Domtar Paper Company, LLC (“Domtar”) is pleased to announce final management approval for the installation of an anaerobic digester treatment system...

Jan

24

2025

Domtar, Office Depot® Charitable Partnerships Support Education

BY: Nicholas.Pearson Since its inception in 2018, Domtar has been a proud supporter of Start Proud!®, Office Depot’s signature back-to-school philanthropic...

Jan

20

2025

PROFILE: Ron Nussman

Ron Nussman Job title: Kingsport Packaging Controller Department: Finance Years with the company: 41 In my 34 years of experience in Kingsport, every mill manager...

Dec

13

2024

Kingsport Mill’s Ellie Southern Receives 40 Under Forty Award

Ellie Southern, human resources generalist for the Kingsport Mill, was recently named to the 32nd class of the 40 Under Forty honorees by the Tri-Cities Business...

Nov

08

2024

Domtar’s Kingsport Mill Unveils New Veterans Wall

Troy Wilson, Kingsport Mill manager, is shown in front of the new Veterans Wall at the mill. KINGSPORT, Tenn. — Domtar unveiled a new Veterans Wall today during a...

Oct

24

2024

Paper Excellence Group Rebrands as Domtar

Unveils New Brand Identity Representing Bright Company Future; Leading Go-To-Market Brands Largely Remain in Place FORT MILL, SC, October 24, 2024 – Paper...

Oct

15

2024

PROFILE: Ellie Southern

Ellie Southern Job title: Human Resources Generalist Department: Human Resources Years with the company: 6 Intern: 2016-2019 Entry-Level HR Advisor:...