Domtar to Install State-of-the-Art Wastewater Treatment System at Kingsport Packaging Mill

Anaerobic Digester is a Long-Term Solution to Reduce Potential Odors from the Facility

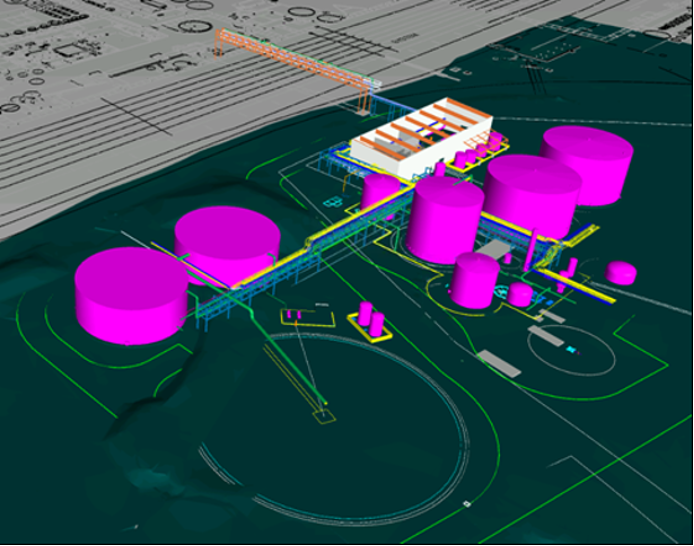

In early 2025, Domtar senior leadership gave final approval for the installation of an anaerobic digester at its Kingsport Packaging Mill. Construction of this state-of-the-art wastewater treatment system is expected to begin during fall 2025, pending permit approvals.

The anaerobic digester — a first for Domtar — will allow the mill to eventually stop using its current wastewater lagoon to treat wastewater as part of its containerboard-making process. Instead, the new treatment system will treat dissolved organic material and convert it into biogas, a renewable energy source that can be used as fuel by the mill to generate steam and electricity for the mill’s manufacturing processes.

Anaerobic technology will give the Kingsport Mill a state-of-the-art wastewater treatment system to reduce potential odors from the mill.

Environmental Benefits

In addition to odor mitigation, the anaerobic digester system has environmental benefits, aligning the project with Domtar’s ongoing commitment to sustainability. These include:

- Using biogas as a renewable fuel source — Offsetting a portion of the natural gas the mill purchases.

- Reduction in greenhouse gas emissions — Capturing methane prevents it from being released into the atmosphere, reducing the facility’s carbon footprint.

- Waste diversion — Organic waste is processed instead of being sent to landfills, reducing landfill usage and leachate generation.

- Nutrient recycling — The digestate byproduct from the process can be used as a fertilizer, promoting circular economy practices.

To learn more about the project, click here.

Project Update

Learn How an Anaerobic Digester Works

Project Timeline

Q1 2025

Q2 2025

Air and stormwater permitting

Q3 2025

Demolition and earthwork; deep foundation

Q4 2025

Critical tie-ins; pile caps/concrete foundations; field-erected tank construction

Q1 2026

Process equipment and piping installation

Q2 2026

Power/controls wiring and control systems installation

Q3 2026

Start checkout and commissioning activities

Q4 2026

New system water trials and ramp-up

Q1 2027

Project closeout and demobilization

FAQs

What is the odor I smell near the mill?

The odor you smell is a result of the decomposition of wood fibers and organic matter in our effluent treatment system that originates in the recycled paper used to make our products. While the odor can sometimes be unpleasant, it is harmless to the environment and community. The decomposition of organic matter takes time for materials to naturally break down. At 23 acres, our effluent treatment process is its own ecosystem.

What is hydrogen sulfide, and should I be concerned about levels?

Hydrogen sulfide (H2S) occurs naturally and is produced when bacteria break down organic material where oxygen is limited such as in a swamp or wetland. It is easily detected as the smell of “rotten eggs.” Just because you smell it does not mean it is harmful to you. While it can be unpleasant, the levels at the mill site — including our wastewater treatment facility — are safe for our employees and contractors as well as the community nearby.

What is the mill doing to mitigate the odor issues?

The mill has installed a system to help block and minimize odor around our wastewater treatment pond. Additionally, supplemental chemical oxidants are being added to the wastewater to improve the efficiency of the decomposition process and minimize odor. We are also currently evaluating what additional engineering solutions may be available.